Communication and Collaboration in the Context of Smart Engineering

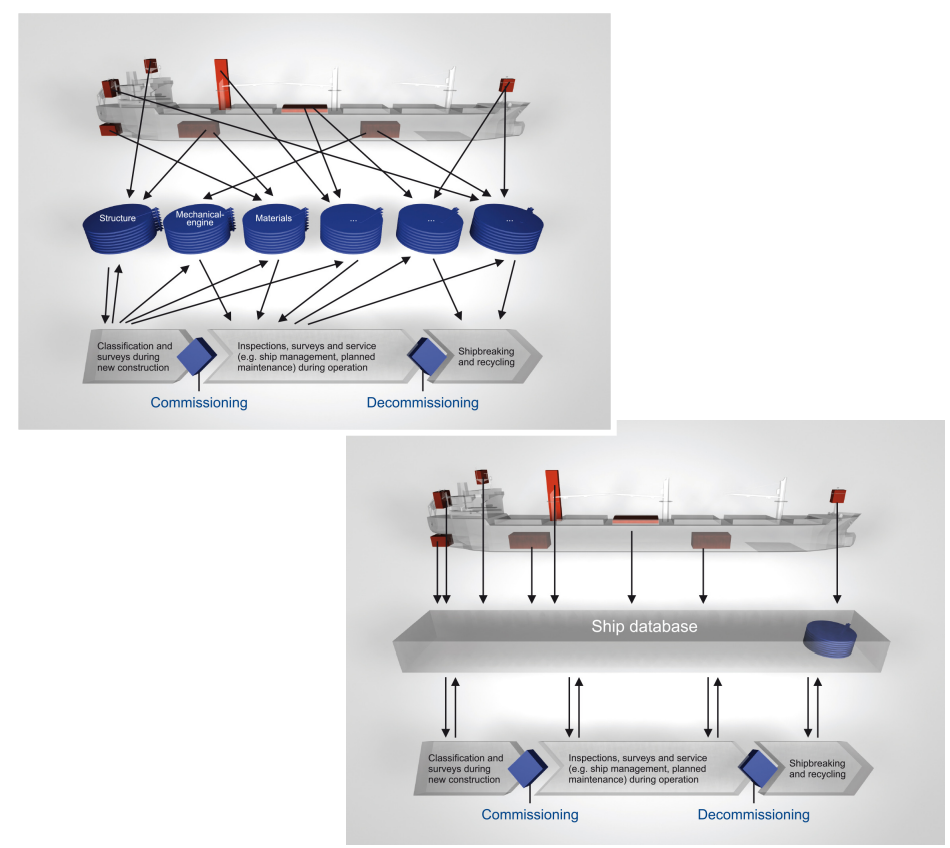

How must a tool infrastructure be designed if it is to make possible smart engineering that truly satisfies the requirements of Industry 4.0? The author is of the opinion that expanding an existing IT backbone, such as PLM, into a “data hub” will only lead to the desired result if important steps in the direction of openness and agility are taken. A position paper on the prerequisites for an IT infrastructure that make the digital master and digital twin possible.