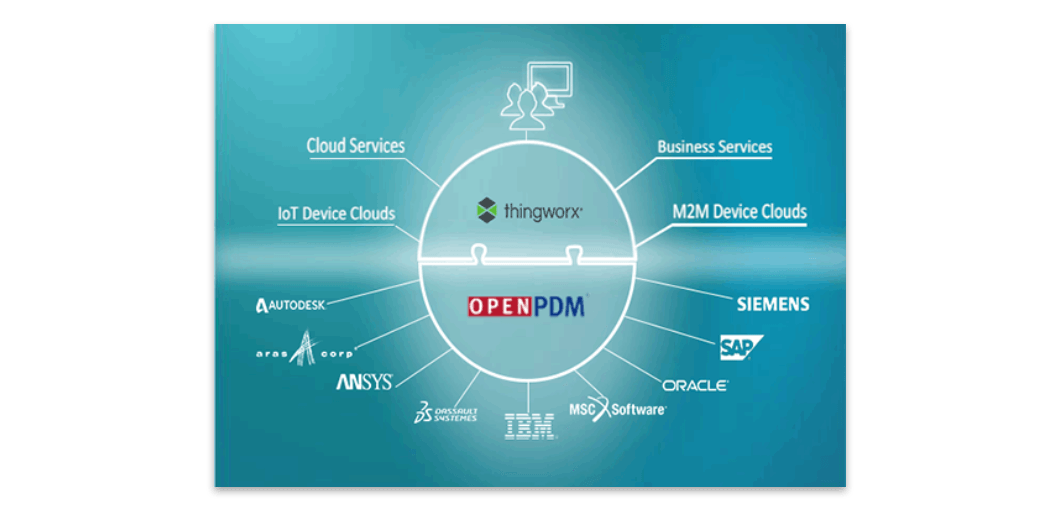

Smart manufacturing starts with smart product engineering and design. By the year 2020, multiple studies have suggested the world’s population will have over 50 billion connected devices. Understanding the Internet of Things (IoT) is complex but vital to the changing landscape of technology within engineering and design. Simply put, IoT is the massive connection of data from internet-ready products. This includes everything from everyday household products such as thermostats and lamps, to manufacturing machines in the automotive, aerospace, and a multitude of other business sectors. Understanding the connectivity of devices between people and people, people and things, and things and things will drive added value for companies in the manufacturing engineering industries. As a result, companies learn about not only the gaps in efficiencies in product manufacturing, but also the customer experience and how customers relate and use the product.