An interview with Iris Gräßler

In collaboration with a consortium of research institutes, software houses and user companies, PROSTEP is developing a model-based solution approach that is intended to simplify impact analysis. In this interview, Professor Iris Gräßler of Paderborn University, who heads up the consortium project, explains why many companies are still struggling with model-based systems engineering (MBSE).

Question: Is systems engineering still feasible without a model-based approach?

Gräßler: The model-based approach lies at the heart of systems engineering. Nowadays, we can no longer imagine product development without comprehensively connected data modeling. The thing about model-based systems engineering is that I can use a model to allow cause-and-effect relationships to be understood. This is all the more important given the many, often contradictory, constraints that have to be taken into account simultaneously during development.

Question: MBSE is supposed to make complexity more manageable. Isn’t it too complex to do that?

Gräßler: That’s something I am often asked. There are no simple solutions for making the complexity of development and of the data and models manageable, however much we wish it were otherwise. But MBSE makes it possible to apply strict logic, thereby making the existing complexity manageable. This entails us working on a higher level of abstraction. It’s a little like higher mathematics, where the goal is to employ abstract thinking to extend the solution space. In product development, we use this approach to solve tricky tasks such as describing the driving behavior. The advantage is that we can consider several alternative solutions simultaneously, which would otherwise simply not be possible.

Question: Sectors such as the automotive industry have been talking about MBSE for years. How far along are companies in implementing it?

Gräßler: The automotive industry is working at full speed to model these cause-and-effect relationships in a comprehensible and transparent way, because the increasing use of software and artificial intelligence means that they can no longer comprehensively test all possible driving situations. The more assistance functions are integrated, the more important it becomes to ensure quality, safety and security. Even for some of the carmakers, this is new territory. Many are still only just starting out as far as MBSE is concerned, but if they manage to convince their developers and implement the approach rigorously, they can gain a long-term competitive advantage.

Question: Is MBSE something that only the carmakers need to be thinking about, or is it also an issue for smaller companies?

Gräßler: It is an issue for all companies and quite a few industries. I’m sure that the carmakers will quickly put on pressure down the supply chain as soon as they have mastered MBSE, just as they demanded the introduction of the CMM L2 standard (capability maturity model) for software development a few years ago. Medical technology, where embedded software and artificial intelligence are used for treatment, also demands a high level of reliability, which we can only guarantee using a model-based approach such as this. Safety aspects are also relevant in the smart home sector, where smart home appliances are connected, for example if I want to switch on the oven while I am out of the house. I think MBSE is relevant for all companies in which the development of requirements and certification play a significant role.

Question: Have small and medium-sized companies already recognized this?

Gräßler: The survey we conducted as part of the ImPaKT project shows that SMEs work with the usual CAD systems and Office applications, and often also use an ERP system. Simulation tools and dedicated MBSE tools, on the other hand, are not very widespread among such companies and, above all, are not yet connected, so that they are not good at making cross-discipline relationships visible. There is a great deal to do here. But actually, it is necessary to take a step back. Not all SMEs are even aware of the fact that MBSE will become an important competitive factor.

Question: What do you think the biggest hurdles in implementing MBSE are?

Gräßler: On the one hand, undoubtedly abstract thinking or what I just called the higher mathematics of development. I have to model at the level of functions and operating principles without having a concrete component in hand. The more experienced a developer, the more entrenched they are in the solutions they are familiar with. The second hurdle is that the benefits of MBSE are difficult or impossible to quantify because, in theory, I would have to run one project with MBSE and one without. But nobody can afford to do that. The third hurdle is the lack of experts. There is a lack of specialists with the appropriate qualifications, because universities have only recently started to focus on MBSE. Here in Paderborn, we have been teaching the subject for some time, but that is not the case everywhere in Germany. Young people first have to be trained, and then they also have to be listened to by the old hands in the companies.

Question: Do the agile process models not also represent a hurdle? Some experts think they are at odds with the MBSE approach.

Gräßler: No, they complement each other just fine. How we model our data is one thing, and how we set ourselves up organizationally is quite another. I can do MBSE just as well with a traditional project organization as with an agile approach. With an agile project, we just have to give some thought up front to how we intend to build our data models for the increments, i.e. we need a superordinate structure at a high level into which we integrate the data models.

Question: How should companies proceed when implementing MBSE?

Gräßler: To start with, they need to analyze exactly where they are starting from and where their employees are. We encounter two extremes in our research projects with industry. There are companies that prefer a top-down approach and think about how they need to change their organizational structure and which tools and methods they want to use to implement model-based development. But there are also companies that first want to get their experienced developers on board. We recommend that such companies start with a pilot project and pick out a complicated case in which it is important that the cause-and-effect chains can be clearly traced. We then model this together so that the employees can see what immediate benefit it brings them. Only then do we discuss company-wide rollout. For major organizational changes, I like to recommend an integrated top-down and bottom-up approach.

Question: So you support companies with the practical implementation of MBSE?

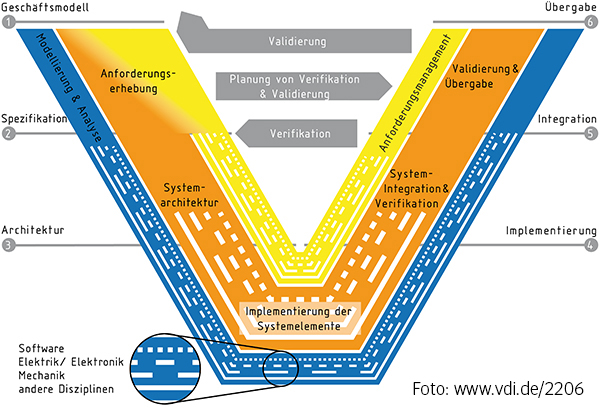

Gräßler: Yes, that’s how we see ourselves. If our doctoral students aren’t familiar with the needs of industry, they won’t become good doctors of engineering. But we can only be good at application-oriented research if we also do basic research at the same time. For example, we have put our hearts into revising the classic V-model, which epitomizes the organizational implementation of MBSE. It was first applied to mechatronic systems in 2004, but now we are talking about systems that are connected to each other and with the Internet of Things and Services. The old V-model could no longer cope with that.

Question: What are the key changes?

Gräßler: We have redrafted VDI 2206 and opened it up for the implementation of digital business models and end-to-end requirements development. We have introduced innovations such as a main feature list for mechatronic and cyber-physical systems – this is a kind of checklist that reminds us to record all requirements. And we’ve added checkpoints with questions between the sections of the V. These tell us whether we’ve done everything that is necessary for any given level of maturity. This can be used both in a traditional stage-gate process and in an agile project.

Question: What other aspects are being researched in the field of MBSE?

Gräßler: A second aspect that is being looked at intensively is the modeling and analysis of cause-and-effect chains. This is a hot topic at present because there are new certification requirements, in particular for carmakers, such as UN-ECE R155 and 156 for the cybersecurity of vehicles and the management of software updates, and these will soon be a prerequisite for type approval. A third focus is the use of artificial intelligence with the objective of partially automating MBSE modeling. Specifically, the ImPaKT project is working on the partially automated assessment of the effects of changes to provide a better basis for decision-making at many points in development.

Question: How is the ImPaKT project coming along?

Gräßler: For model-based impact analyses, we first have to identify the cause-and-effect relationships, model them and develop intelligent algorithms for evaluating them. All of this is done against the backdrop of engineering change management with the aim of making technical changes manageable within the company. This entails consideration of associated topics such as the question of how we can integrate established software products from the individual disciplines and connect the sub-models from the fields of mechanical engineering, electrical/electronic engineering and software, but also from pneumatics, acoustics or optics. PROSTEP is an important partner in this context because interface technology is essential for this.

We are on schedule with all the work packages, although we have rarely been able to meet up in person because of the coronavirus. This year, we will close out with a minimum viable product representing some 80 percent of the basic functionality.

Professor Gräßler, thank you very much for talking to us.

(This interview was conducted by Michael Wendenburg).

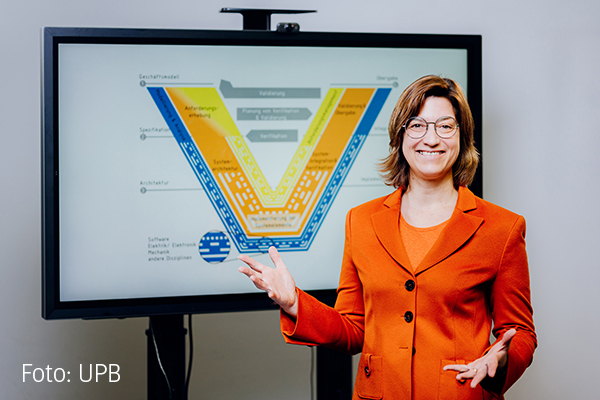

About Professor Gräßler

Professor Iris Gräßler has held the Chair of Product Design at the Heinz Nixdorf Institute of Paderborn University since 2013. Her research focuses on model-based product engineering to create intelligent technical systems. Gräßler studied at RWTH Aachen University, where she earned her doctorate in the Production Systems department in 1999 and qualified as a professor in 2003. Before her appointment to Paderborn, she worked for several years in a number of management positions in product development, production systems and change management at Robert Bosch GmbH. Gräßler is a member of various VDI committees for the standardization and further development of design engineering methods.