Digital Twins offer the possibility to simulate the behavior of physical assets, to monitor them during operation and to continuously improve them. The data and models from planning and development form the context in which the operating data can be interpreted correctly. Putting them together from the wealth of available information is an essential prerequisite for the use of digital twin applications.

The Digital Twin is the digital image of a physical object or system, which can be a product, a production plant, but also a company or a process. The Digital Twin connects virtual planning and development models with the real product or production world in order to give people a better insight into the system and its condition or behavior. A vision in the sense of Industrie4.0 is to enable technically complex systems to control themselves autonomously and behave more intelligently through digital algorithms, virtual models and status information.

The functional relationships of a product or a production plant are defined based on customer requirements and in consideration of a multitude of legal requirements in product planning and development. Without knowledge of these interrelationships, the operating data that the real asset captures and provides in its later product life cannot be interpreted correctly. If you do not know how a machine or system is actually supposed to function, it is not possible to identify the causes of deviations from this target state or behavior beyond doubt and take appropriate countermeasures. At the same time, knowledge of the history of origins is also important in order to be able to assess for what reason, for example, a bearing has failed and which other machines could also be affected by the problem.

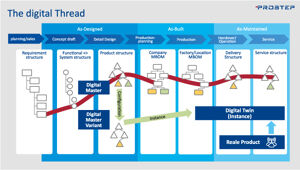

This connection between the real asset and the development and planning models describing its history is called a digital thread. It is the digital “red thread” that links the information of a real product instance across processes and IT systems. On the one hand, this makes it possible to bring together all the information from the life cycle of the product instance or the real asset and thus forms the basis for the creation of a digital thread. Without a digital thread, the digital twin can be reproduced manually, but it is difficult or impossible to keep it up to date. On the other hand, traceability along the Digital Thread allows decisions in development and production to be questioned and optimization potential to be identified with the help of the operating data.

Management of product configurations

From a PLM point of view, the starting point of the digital twin is a specific configuration of the product or production system, for example the asset in its delivered state. This includes not only mechanical, electrical/electronic and software components with their models, but perhaps also service-relevant information, such as the service life of certain components. Bringing this information together and maintaining it manually is time-consuming and error-prone, especially since the configuration changes over the course of the product’s life, whether through software updates or other measures in the context of maintenance or further development of the asset. The expectation of today’s PLM systems is to automatically extract the configuration for the Digital Twin and keep it up-to-date.

We speak here of the concept of Configuration Lifecycle Management (CLM), which makes it possible to generate temporally valid views of the product across IT system boundaries and to manage product configurations across all phases of the product lifecycle. The main function of CLM is to create and keep consistent the various views of the digital product model during the life cycle, and to document their validity over time. To do this, it uses cross-system and cross-discipline baselines. These baselines document the state of the configuration at a certain point in time or maturity level and thus also control the representation of the Digital Twin. They enable companies to immediately and reliably answer the question at any point in the process whether and how the product or asset meets the requirements placed on it or in what state the asset was at a defined point in time, for example, which product configuration was delivered to the customer.

In order to manage the configuration of a product along its entire life cycle in a traceable manner, the use of a powerful PLM integration platform with connectors to all IT systems involved is required. As an intermediate layer spanning all IT systems, it creates the prerequisite for bringing together the information from the individual IT systems in a way that corresponds to the digital thread concept.

Cross-company collaboration

In industries such as mechanical and plant engineering or shipbuilding, companies face the challenge that the manufacturer who builds and provides the Digital Twin is not necessarily the operator and user who feeds it with operational data. Both the digital data and the operating data, or at least part of it, must therefore be exchanged and synchronized across companies in order to keep the Digital Twin up to date and to be able to use the operating data for the continuous improvement of real assets. Questions such as data security, protection of intellectual property and ownership of the data therefore play a very central role in the development and use of a digital twin application.

More and more customers today require their suppliers to deliver digital data and models to support Digital Twin applications along with the physical assets. CLM can be used to control not only the amount of information provided, but also the level of detail of the information and the formats in which it is delivered. They can be compiled largely automatically and made available to the customer as a data package, for example in 3D PDF format.

In order to maintain digital consistency in cooperation across company boundaries, the exchange partners must first agree on the scope of the information to be exchanged and agree on common standards for handling this information. But the central question is where the Digital Twin should live? PROSTEP is convinced that it is advisable to set up a joint collaboration platform for this purpose, which will become part of the information model. This platform will provide customers with the information they need to build their Digital Twin application while the development process is still underway and will also allow them to synchronize changes to the master models during operation if necessary. The common platform can also be used to link parts of the operating data required by the manufacturer for new service offers such as predictive maintenance or product improvements with the Digital Thread.

Three building blocks for the Digital Twin

The foundations for the Digital Twin are already laid in product development and production planning. To bring it to life and keep it alive, the digital umbilical cord must not be cut. This is why an integration platform is needed that makes the digital information from the various authoring and data management systems available at any time. A powerful configuration management system that manages the relationships between the information scopes and their validity is essential for building a Digital Twin. However, digital consistency is not a one-way street. In order to derive maximum benefit from the product twin in terms of closed loop engineering, traceability between Digital Twin and Digital Thread must be ensured. The creation of a collaboration platform maintains digital consistency even beyond company boundaries.

By Lars Wagner

Posted with permission from PROSTEP AG.