ALM PLM Integration with ThingWorx

ALM PLM Integration with IoT

Smart manufacturing starts with smart product engineering and design. By the year 2020, multiple studies have suggested the world’s population will have over 50 billion connected devices. Understanding the Internet of Things (IoT) is complex but vital to the changing landscape of technology within engineering and design. Simply put, IoT is the massive connection of data from internet-ready products. This includes everything from everyday household products such as thermostats and lamps, to manufacturing machines in the automotive, aerospace, and a multitude of other business sectors. Understanding the connectivity of devices between people and people, people and things, and things and things will drive added value for companies in the manufacturing engineering industries. As a result, companies learn about not only the gaps in efficiencies in product manufacturing, but also the customer experience and how customers relate and use the product.

How does ALM PLM Integration with IoT Impact Manufacturing?

ThingWorx, the IoT platform from PTC, leverages sensory data and aggregates information into one system. But what if users want to incorporate PLM/ALM data into the view? This add several layers of complexity when users need to view PLM/ALM information from various platforms within the ThingWorx IoT platform. To get the most out of this new data, manufacturing companies leverage sensory information taken from their machines and provide a traceable trail, a digital thread of information back to the design and engineering PLM/ALM systems. Because of the disparate PLM, ALM, SDM systems utilized by differing companies, it becomes challenging to utilizing this data across different vendor solutions.

ThingWorx Integration with ALM and PLM

During the production or use of a product, the increased network of sensor data will reveal new valuable data sets to ThingWorx services. This new data can be synthesized within ThingWorx architecture into PLM data. This could be in the form of a problem report or engineering change request generated in your PLM if there is a known higher percentage failure of a product. You may discover that customers are focusing on certain features or product paths that could generate new enhancement opportunities or requirements in ALM. Bringing the traceability from the user experience back to the initial design can open a world of unique benefits to your organization.

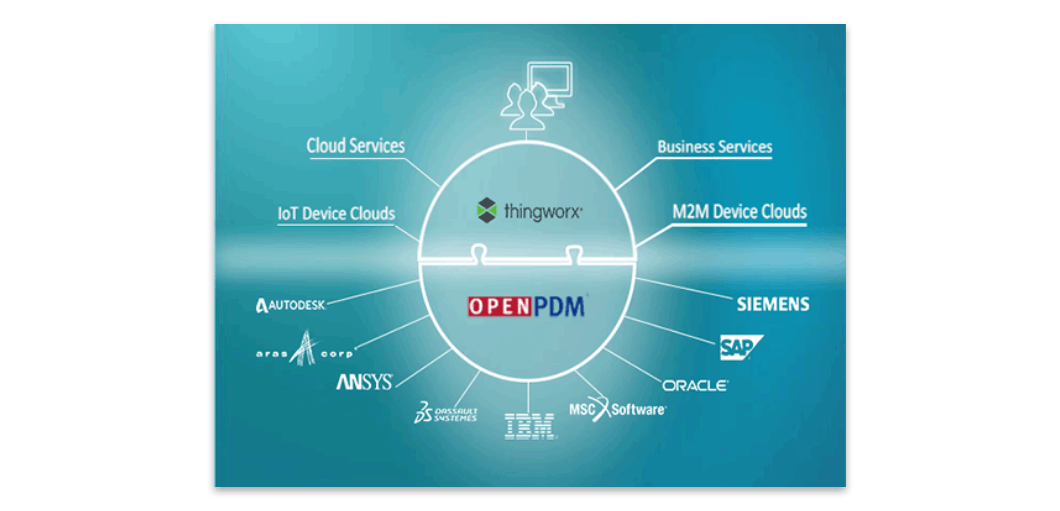

PROSTEP’s OpenPDM integration to ThingWorx architecture may also provide a federated interface to discover all the data within PLM, ALM, SDM and other systems. Utilizing PROSTEP’s OpenPDM ThingWorx connector with PTC Navigate allows users to easily discover and utilize data within the connected systems. Design viewables such as 3DPDF TDP’s, lightweight viewables, documents, requirements, and other artifacts are all accessible through the mash-up federated template in Thingworks IoT platform.

OpenPDM is the market leading vendor-to-vendor PLM integration platform and has created a first to market solution for PTC’s ThingWorx connectivity. It enables ThingWorx data integration between domains and disciplines, across corporate borders between systems from different vendors. For the last 15 years OpenPDM has been a solution for integration and migration of engineering data. PROSTEP OpenPDM ThingWorx connector is a first to market, comprehensive, proven platform for bi-directional flexible integrations for:

- ThingWorx Connector to SAP PLM

- ThingWorx Connector to 3DEXPERIENCE

- ThingWorx Connector to SIEMENS Teamcenter

ThingWorx Integration from PROSTEP

Work with PROSTEP

Tel: +1 877.678.3701

Email: infocenter@prostep.com

Questions? Contact Us